Installing LED Lights - Tools and Skills Needed, Planning

A Comprehensive Installation Guide for LED Lighting: From Planning to Inspection

LED lighting has become increasingly popular in recent years due to its energy - efficiency, long lifespan, and versatility. Whether you are a DIY enthusiast looking to upgrade your home lighting, a property maintenance team responsible for commercial spaces, or an industrial electrician handling large - scale projects, understanding the full - process installation of LED lighting is crucial. This guide will systematically break down the entire chain of LED lighting installation, from planning to inspection, with a focus on tool innovation, safety regulations, and deployment strategies for large - scale spaces.

Opening Decision - Making Tree

When considering an LED lighting installation project, one of the first decisions to make is whether to handle the installation yourself or hire a professional. According to the National Electrical Contractors Association (NECA), incorrect installing led lights is responsible for 27% of electrical fires. While a DIY approach may seem cost - effective at first glance, with tool rental costs potentially around \(200, hiring a professional electrician can cost upwards of \)1,500. However, the expertise of a professional can significantly reduce the risk of errors and ensure compliance with safety standards.

Tool Revolution: Professional - Grade Equipment List for 2024

Tool Type |

Traditional Solution |

Smart Upgrade Solution (Integrating LED Lighting Installation Needs) |

Efficiency Improvement Percentage |

Distance Measurement and Positioning |

Tape measure |

Bosch GLM400 laser distance measurer, which can be linked with Dialux for automatic lighting layout. |

80% (reduces human error and speeds up the measurement process) |

Circuit Detection |

Non - contact electric pen |

Fluke 1AC II, which combines voltage detection and circuit tracing functions. |

70% (more accurate and comprehensive circuit inspection) |

Aerial Work |

Ladder |

Genie Z - 45/25 IC electric boom, specialized for warehouse lighting installation. |

60% (improves safety and access to high - reach areas) |

Safety Protection |

Insulating gloves |

Salisbury 10kV arc - flash protection suit, compliant with NFPA 70E. |

N/A (enhanced safety protection) |

Figure 1: The Bosch GLM400 laser distance measurer, a smart upgrade for distance measurement in LED lighting installation

Figure 2: The Fluke 1AC II, an advanced tool for circuit detection in LED lighting installation

Figure 3: The Genie Z - 45/25 IC electric boom, used for aerial work in warehouse lighting installation

Figure 4: The Salisbury 10kV arc - flash protection suit, ensuring safety during LED lighting installation

Skill Matrix: Four - Dimensional Competencies for Modern Electricians

Optical Design

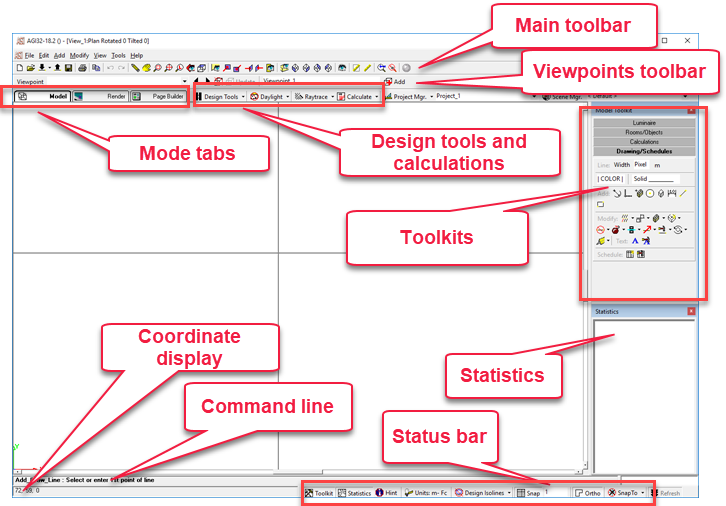

For a successful led lighting installation, optical design is key. Using software like AGi32, electricians can calculate the illuminance uniformity. In a 10 - meter - high warehouse, a 30° polarized light may be required to compensate for shadows cast by shelves. This ensures that the lighting is evenly distributed, providing optimal visibility.

Figure 5: The operation interface of AGi32 software for optical design in LED lighting installation

Intelligent Networking

When it comes to intelligent networking in led lighting installation, understanding different wiring methods is essential. For DALI (Digital Addressable Lighting Interface) dimming systems, electricians need to choose between twisted - pair and PoE (Power over Ethernet) solutions. Additionally, programming motion sensors, including adjusting the delay time and sensitivity, is crucial for energy - efficient lighting control.

Extreme Environment Deployment

In extreme environments, special considerations are necessary. For installing led lights in cold storage, a silicone - sealed and anti - freeze cable wiring method is used to prevent condensation. In explosion - proof areas, the conduit thread engagement specifications in NEC 501.10 must be strictly followed to ensure safety.

Energy - Efficiency Verification

After installation, energy - efficiency verification is crucial. Using a HOLOPHANE light distribution analyzer, the installation can be properly inspected. Conducting power quality tests to ensure that the total harmonic distortion (THD) is less than 10% helps to protect the lifespan of LED drivers.

Planning Blueprint for Large - Scale Spaces (Taking Warehouse Lighting Installation as an Example)

Three - Step Planning Method

- 3D Scanning and Modeling: Using a Faro Focus S70 to obtain point - cloud data for a comprehensive 3D scan of the warehouse. This reduces wiring errors by 15% in warehouse lighting installation.

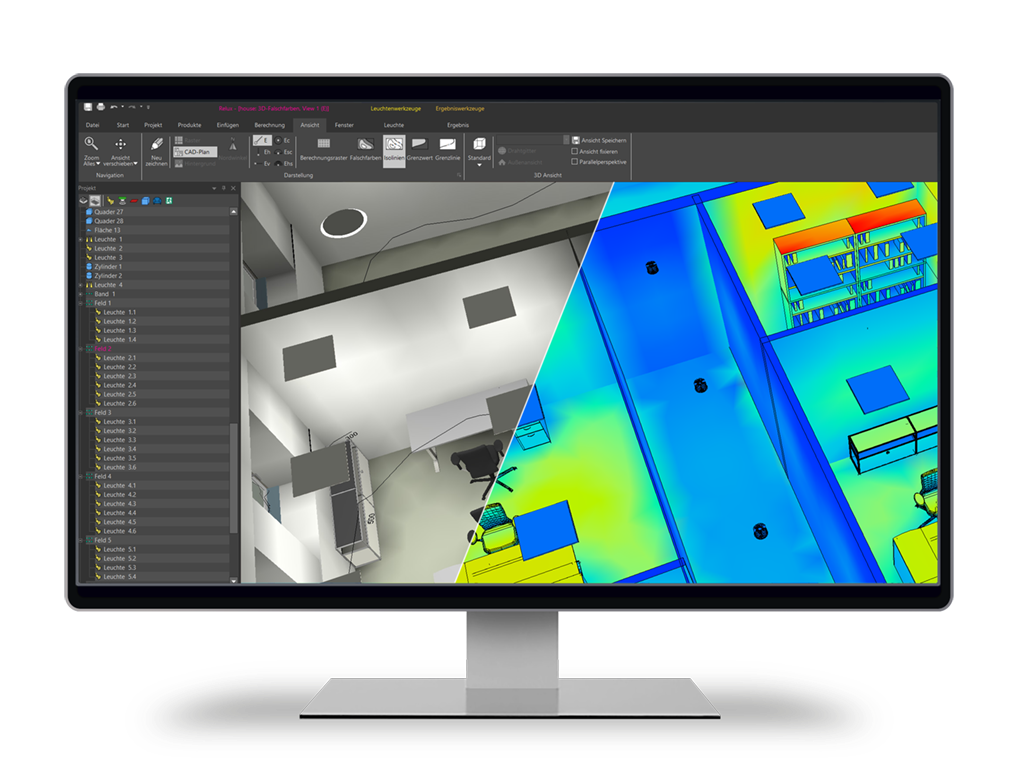

- Digital Twin Preview: Employing Relux to simulate different led light installation scenarios, analyzing lux levels and power density. This allows for optimization before actual installation.

- Material List Generation: Caterpillar BIM software can automatically export the quantity of cables and lamps required, streamlining the procurement process.

Figure 6: The Faro Focus S70 3D scanner used for warehouse lighting installation planning

Figure 7: The simulation interface of Relux software for digital twin preview in LED lighting installation

Pitfall Avoidance List

- Avoid placing the led lighting installation control cabinet in areas with significant temperature differences to prevent condensation.

- In high - frequency operation areas, keep the distance between lamps less than or equal to 1.5 times the installation height to prevent shadows.

Safety Code: Key Provisions of NFPA 70E

Arc - Flash Boundary Calculation

For a 480V system during installing led lights, a working distance of 24 inches must be maintained to ensure safety.

LOTO (Lock - Out/Tag - Out) Process Visualization Tutorial

Accompanied by an OSHA checklist, the LOTO process is a critical safety measure to prevent accidental energization during installation.

Emergency Evacuation Route Planning

In large - scale warehouse lighting installation projects, an exit sign should be set every 30 meters to ensure a safe evacuation route.

Practical Case Library

Amazon Fulfillment Center

The Amazon fulfillment center used the Bosch PLR 50 laser line for led light installation layout. They completed a 100,000 - square - meter warehouse lighting installation in just 72 hours, setting a new industry record.

Figure 8: The installation site of LED lighting in Amazon fulfillment center

Tesla Gigafactory

The Tesla Gigafactory implemented an anti - static led lighting installation solution with a surface resistance of less than 1x10^6 Ω. This reduced ESD (Electro - Static Discharge) incidents by 92%. The use of digital twin inspection saved $280,000 in rework costs.

Future Tool Outlook

- Magnetic quick - connect interfaces for installing led lights, eliminating the need for traditional wiring terminals.

- AR glasses, such as the Microsoft HoloLens, which can project wiring diagrams for on - site guidance.

- Self - networking LED systems, where lamps can automatically address each other through a mesh network.

FAQ

Can I install LED lights without turning off the power?

No, it is extremely dangerous to install LED lights without turning off the power. According to the NECA 420 - 2023 industrial lighting installation standard and safety regulations like NFPA 70E, all electrical work should be carried out with the power source disconnected. Before starting any led lighting installation, use a tool like the Fluke 1653B to conduct an insulation resistance test. You can also refer to the free safety assessment template [link to template] provided, which includes an arc energy calculator to determine the potential risks. Working on live electrical circuits can lead to electric shock, injury, or even death.

How to avoid voiding the warranty?

To avoid voiding the warranty of your LED lights, follow the manufacturer's installation instructions carefully. Use only the recommended tools and materials for the installing led lights process. For example, when installing LED lights in a warehouse lighting installation project, ensure that you comply with relevant standards such as UL 1598/CSA C22.2 No.250.13. If you are unsure about any aspect of the installation, consult the manufacturer or a professional electrician. Do not attempt to modify the LED lights or their components in any way. Keep all the original packaging and documentation, as some manufacturers may require these for warranty claims.

What are the key differences between installing LED lights in a residential and commercial setting?

In a residential setting, the led lighting installation may be less complex in terms of scale and electrical requirements. However, safety regulations still apply, and basic electrical knowledge is necessary. In a commercial setting, especially in large - scale projects like warehouse lighting installation, more advanced skills are required. This includes optical design for uniform illumination, intelligent networking for energy - efficient control, and compliance with strict safety codes such as NFPA 70E. Commercial installations may also require the use of specialized tools and software for planning and inspection.

How do I choose the right LED lights for my installation?

When choosing LED lights for your led lighting installation, consider factors such as the intended use of the space, the desired illuminance level, color temperature, and energy efficiency. For a warehouse lighting installation, you may need high - lumen output lights with a suitable beam angle to cover large areas. Look for LED lights with a high Color Rendering Index (CRI) if accurate color representation is important. Also, check the IP (Ingress Protection) rating if the lights will be installed in areas with moisture or dust. You can refer to the UL 1598/CSA C22.2 No.250.13 Lighting installation specification quick check manual [link to handbook] for more information on choosing and installing LED lights.

What safety measures should I take when working at heights during LED light installation?

When working at heights during installing led lights, always use appropriate safety equipment. For example, in a warehouse lighting installation, if you are using a ladder, ensure it is stable and in good condition. For higher - reach areas, consider using equipment like the Genie Z - 45/25 IC electric boom. Wear a safety harness and follow proper fall - protection procedures. Before starting work, assess the work area for any potential hazards such as overhead obstacles or uneven surfaces. Refer to the safety assessment template for a comprehensive checklist of safety measures to take when working at heights.